Lines, it might not be possible to achieve the required variance with a hydraulic nozzle. When variable flow rates are required due to, say, different product This, however, will alter other important spray characteristics such as droplet size. With a normal hydraulic nozzle flow rates could only be controlled by varying the fluid pressure. Because the on/off cycle is so fast the resulting spray remains very evenly distributed even when This would halve the overall flow rate at any given pressure. So, for example,Ī half flow could be achieved by having a 0.05 second on to 0.05 second off cycle time. This is achieved by pulsing the nozzle very rapidly, (pulse width modulation - PWM). With such fast and reactive on/off cycle times the Electric HydroPulse can vary the flow from the nozzle without varying the fluid pressure. When combined the Electric HydroPulse nozzles, the FlexFlow control panel and the spray manifolds represent a complete, precision spraying system. Furthermore, we can design and buildĪll the necessary spray manifolds to position the nozzles correctly. The FlexFlow control panel is an off-the-shelf box built for precision spray control.

#Electric solenoid valve for sprayer software

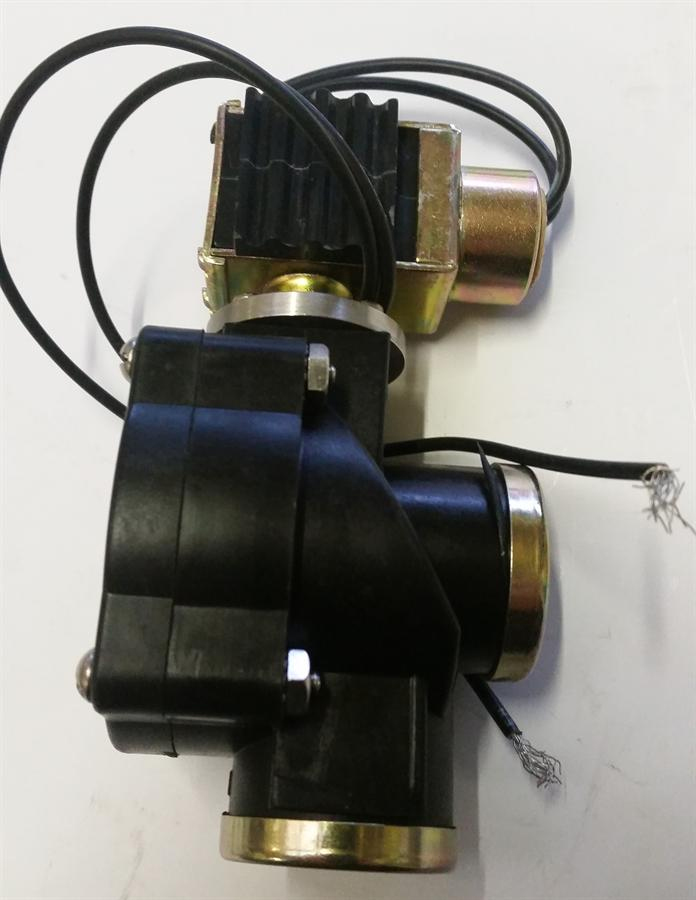

In addition to the electrically modulated spray nozzles, SNP can also supply the hardware and software for controlling the nozzles. The nozzle can be cycled on and off up to 150 times per second. This means the reaction time of the shut-off The solenoid valve is positioned inside the nozzle so that it is very close to the orifice. The cost of ball valves is more but you will be happier in the long run.The Electric HydroPulse nozzle has an integrated solenoid valve to rapidly regulate the on/off cycle of the nozzle.

#Electric solenoid valve for sprayer how to

How to Extend the Life of Your Sprayer Valves Although the initial investment may be greater, you will see a great deal longer life with an electric ball valve. If you spray hundreds or even thousands of acres every year, you most likely are well acquainted with electric ball valves, but if you have a small sprayer and do not spray many acres, you still may be frustrated by the number of times you need to repair or replace solenoid valves. How Long Will A Solenoid Valve Last Compared to A Ball Valve? Ball valves also provide a better seal for a longer time, especially when they are flushed out with freshwater or a tank neutralizer and cycled before being stored for a long period of time. The valve actuator/motor is made to be sealed up against moisture or debris. There is no coil, instead, there is an electric motor that drives the gearbox to turn the ball. Some of the causes are the plunger not operating correctly, wrong voltage, or coil short circuit.Įlectric ball valves have a signal or switch wire that tells the motor to turn the ball and when to stop. Resistance will cause the coil to heat up and burn out. Solenoid coils require constant electrical current to keep them open or closed, depending on whether you have a normally open or normally closed valve. Unlike solenoid valve coils, the motorized actuators on electric ball valves do not have the risk of “burning up”. Why Electric Ball Valves are Better Than Solenoid Valves for Sprayers Note: If you have been using solenoid valves with a sprayer controller like the TeeJet 744A or similar, you will need to change your wiring in order to use ball valves. They are used for section control on self-propelled sprayers, planters, water trucks, etc. They can also be used as a regulating valve when they are equipped with the right type of actuator.

An electric ball valve can be used more easily with different rate controllers and switch boxes.

0 kommentar(er)

0 kommentar(er)